Optimization of Electroplating Thickness Quality at Hip Joint Implant using the Taguchi Method

DOI:

https://doi.org/10.22219/JTIUMM.Vol20.No1.45-52Keywords:

hip joint implant, hard chrome, electroplating thickness, taguchi methodAbstract

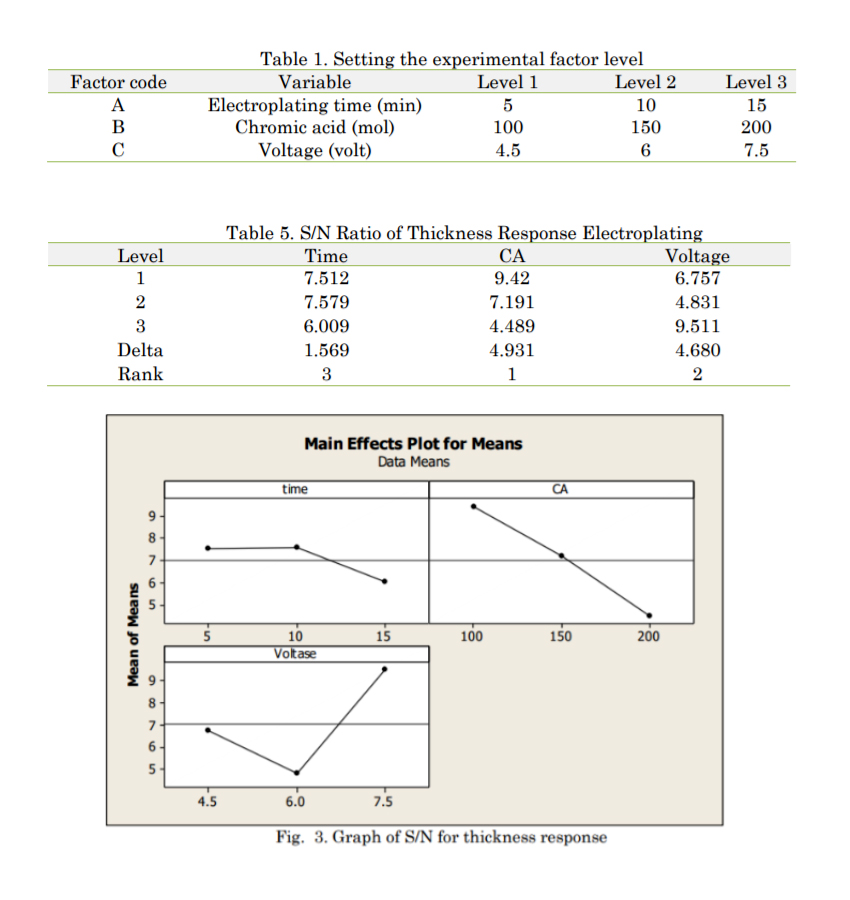

The hip joint is one of the most often used joints by humans in their activities. The hip joint can be impaired if an accident or an illness such as osteoarthritis-affected. It makes the patients need to get implants to restore their productivity. The implant must be biocompatible, bioactive, and have high strength and resilience to prevent damage. The implants in this study were made from 304 Stainless Steel. One of the stages in making implants is the electroplating process. The electroplating method implemented is hard chrome. Some operating conditions that affect the electroplating process and are used as independent variables are the concentration of chromic acid, electrical voltage, and length of coating time. This study aims to Optimization of Electroplating Thickness Quality at Hip Joint Implant. This study uses the Taguchi method to design the experiment and to obtain the optimum electroplating thickness results. ANOVA is used to obtain the effective prediction of the significance level. Process ANOVA was helped Minitab 16. Based on the ANOVA, it is known that the most significant factor for the electroplating thickness is the concentration of chromic acid, the voltage, and the least influential factor is the electroplating time.

Downloads

References

[1] P. Cardiff, A. Karač, D. FitzPatrick, R. Flavin, and A. Ivanković, "Development of a hip joint model for finite volume simulations," Journal of biomechanical engineering, vol. 136, p. 011006, 2014. https://doi.org/10.1115/1.4025776

[2] T. Sato and N. Sato, "Clinical relevance of the hip joint: Part I–Review of the anatomy of the hip joint," International Musculoskeletal Medicine, vol. 37, pp. 141-145, 2015. https://doi.org/10.1179/1753615415Y.0000000005

[3] A. M. Wood, T. M. Brock, K. Heil, R. Holmes, and A. Weusten, "A review on the management of hip and knee osteoarthritis," International journal of chronic diseases, vol. 2013, 2013. http://dx.doi.org/10.1155/2013/845015

[4] J. Salmon, A. Rat, J. Sellam, M. Michel, J. Eschard, F. Guillemin, et al., "Economic impact of lower-limb osteoarthritis worldwide: a systematic review of cost-of-illness studies," Osteoarthritis and Cartilage, vol. 24, pp. 1500-1508, 2016. https://doi.org/10.1016/j.joca.2016.03.012

[5] T. De Caluwé, C. Vercruysse, H. Declercq, D. Schaubroeck, R. Verbeeck, and L. Martens, "Bioactivity and biocompatibility of two fluoride containing bioactive glasses for dental applications," Dental Materials, vol. 32, pp. 1414-1428, 2016. https://doi.org/10.1016/j.dental.2016.09.014

[6] S. Nag and R. Banerjee, "Fundamentals of medical implant materials," ASM handbook, vol. 23, pp. 6-17, 2012.

[7] B. J. Love, Biomaterials: a systems approach to engineering concepts: Academic Press, 2017.

[8] K. C. Walley, M. Bajraliu, T. Gonzalez, A. Nazarian, and J. A. Goulet, "The chronicle of a stainless steel orthopaedic implant," The Orthopaedic Journal at Harvard Medical School, vol. 17, pp. 68-74, 2016. http://www.orthojournalhms.org/17/article68_74.html

[9] Rabin, "Immune Response to Implants," Medscape, 2017.

[10] V. Gujarat, Pharmaceuticals Government of Gujarat. Implants Coating Facility, 2017.

[11] A. Setiawan, "Pengaruh Prosentase Karbon Pada Baja Karbon Proses Electroplating Tembaga," UMS, Surakarta, 2014.

[12] I. A. S. Adnyani and A. Triadi, "Pengaruh Kuat Dan Distribusi Arus Terhadap Ketebalan Dan Kekerasan Lapisan Krom Pada Stoneware Dan Earthenware," Teknologi Elektro, vol. 8, pp. 76-81, 2009.

[13] Balseal, Chrome Plating: A Guide for Selecting The Type of Chrome Plating for Use in Contact with Bal Seal spring-energized Seals in Rotary and Reciprocating Service, 2016.

[14] Bapat, "Coating Implants," OMTEC, 2014.

[15] H. S. Shim, "The mechanical behavior of LTI carbon dental implants," Biomaterials, medical devices, and artificial organs, vol. 4, pp. 181-192, 1976. https://doi.org/10.3109/10731197609118649

[16] Ridlwan, "Pengaruh Jarak Anoda Katoda Teknik Elektroplating Seng Terhadap Ketebalan Dan Kekerasan Hasil Lapisan," UNNES, Semarang, 2016.

[17] S. Raharjo, "Pengaruh Variasi Tegangan Listrik dan Waktu Proses Elektroplating terhadap Ketebalan serta Kekerasan Lapisan pada Baja Karbon Rendah dengan Krom," Universitas Diponegoro, 2010. http://eprints.undip.ac.id/23808/

[18] A. P. Jadid, M. Pourjafar, and A. Banaei, "Optimization of Electroplating Conditions of Chromium (VI) Using Taguchi Experimental Design Method," Anal. Bioanal. Chem, vol. 6, pp. 16-27, 2014.

[19] S. M. Baligidad, U. Chandrasekhar, K. Elangovan, and S. Shankar, "Taguchi’s Approach: Design optimization of process parameters in selective inhibition sintering," Materials Today: Proceedings, vol. 5, pp. 4778-4786, 2018. https://doi.org/10.1016/j.matpr.2017.12.051

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Sela Angela Putri, Eko Pujiyanto, Joko Triyono

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.