Development of Risk Evaluation and Mitigation Systems for Logistics System

DOI:

https://doi.org/10.22219/JTIUMM.Vol21.No1.92-103Keywords:

Risk Management, Mitigations, Logistic, Risk evaluationAbstract

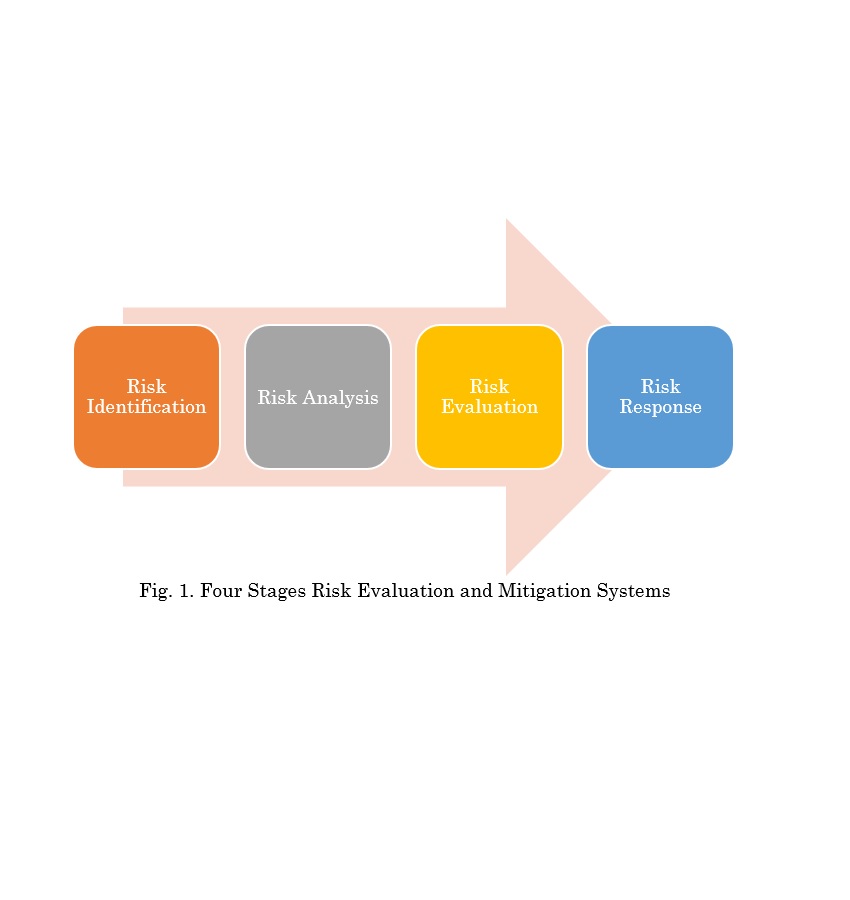

Logistic activities are significant activities that pose various risks for the company. These risks can affect the company’s performance. To be able to compete in the globalization era, companies need proper risk management. This study aimed to develop Risk Evaluation and Mitigation Systems. We offered four stages: risk identification, risk analysis, risk evaluation, and risk response. A case study was conducted to implement the proposed Risk Evaluation and Mitigation Systems. The results indicated that the proposed Risk Evaluation and Mitigation Systems were proven to be appropriately applied to evaluate company risks and provide mitigation recommendations.

Downloads

References

[1] Ö. F. Gürcan, İ. Yazıcı, Ö. F. Beyca, Ç. Y. Arslan, and F. Eldemir, “Third Party Logistics (3PL) Provider Selection with AHP Application,” Procedia - Social and Behavioral Sciences, vol. 235, pp. 226-234, 2016/11/24/ 2016, https://dx.doi.org/10.1016/j.sbspro.2016.11.018.

[2] F. Ibrahim, “Integrated Supply Chain Contract Model With Drop-Shipper Players,” 2018, Supply chain contract, delay in payment, penalty contract vol. 19, no. 1, p. 15, 2018-02-27 2018, https://dx.doi.org/10.22219/JTIUMM.Vol19.No1.58-72.

[3] A. Rusdiansyah and A. Aryusamalia, "Penentuan Jumlah dan Kombinasi Jenis Kendaraan dengan Saving Heuristik pada Perusahaan Jasa Logistik Pihak Ketiga," 2008, saving heuristic, consolidation delivery, service logistics third party vol. 8, no. 2, p. 7, 2008-08-20 2008, https://dx.doi.org/10.22219/JTIUMM.Vol8.No2.172-178.

[4] P. S. Ceryno, L. F. Scavarda, and K. Klingebiel, “Supply chain risk: empirical research in the automotive industry,” Journal of Risk Research, vol. 18, no. 9, pp. 1145-1164, 2015/10/21 2015, https://dx.doi.org/10.1080/13669877.2014.913662.

[5] X. Li, “Operations Management of Logistics and Supply Chain: Issues and Directions,” Discrete Dynamics in Nature and Society, vol. 2014, p. 701938, 2014/06/10 2014, https://dx.doi.org/10.1155/2014/701938.

[6] M. Ulfah, M. S. Maarif, and S. R. Sukardi, "Analisis dan perbaikan manajemen risiko rantai pasok gula rafinasi dengan Pendekatan house of risk," Journal of Agroindustrial Technology, vol. 26, no. 1, 2016, https://journal.ipb.ac.id/index.php/jurnaltin/article/view/13129.

[7] P. Raj Sinha, E. Whitman Larry, and D. Malzahn, “Methodology to mitigate supplier risk in an aerospace supply chain,” Supply Chain Management: An International Journal, vol. 9, no. 2, pp. 154-168, 2004, https://dx.doi.org/10.1108/13598540410527051.

[8] W. Ho, T. Zheng, H. Yildiz, and S. Talluri, “Supply chain risk management: a literature review,” International Journal of Production Research, vol. 53, no. 16, pp. 5031-5069, 2015/08/18 2015, https://dx.doi.org/10.1080/00207543.2015.1030467.

[9] S. Chopra and M. S. Sodhi. (2004) Managing Risk To Avoid Supply-Chain Breakdown. MIT Sloan Management Review. 53-61.

[10] C. Colicchia and F. Strozzi, “Supply chain risk management: a new methodology for a systematic literature review,” Supply Chain Management: An International Journal, vol. 17, no. 4, pp. 403-418, 2012, https://dx.doi.org/10.1108/13598541211246558.

[11] A. Ghadge, S. Dani, and R. Kalawsky, “Supply chain risk management: present and future scope,” The International Journal of Logistics Management, vol. 23, no. 3, pp. 313-339, 2012, https://dx.doi.org/10.1108/09574091211289200.

[12] I. Nyoman Pujawan and H. Geraldin Laudine, “House of risk: a model for proactive supply chain risk management,” Business Process Management Journal, vol. 15, no. 6, pp. 953-967, 2009, https://dx.doi.org/10.1108/14637150911003801.

[13] W. A. Teniwut, “Challenges in Reducing Seaweed Supply Chain Risks Arising Within and Outside Remote Islands in Indonesia: An Integrated MCDM Approach,” in Sustainability Modeling in Engineering, pp. 271-291.

[14] N. Ummi, P. Ferro Ferdinant, A. Irman M.S, and A. Gunawan, “Integration house of risk and analytical network process for supply chain risk mitigation of cassava opak chips industry,” MATEC Web Conf., vol. 218, p. 04022, 2018, https://dx.doi.org/10.1051/matecconf/201821804022.

[15] K. Govindan and A. Chaudhuri, “Interrelationships of risks faced by third party logistics service providers: A DEMATEL based approach,” Transportation Research Part E: Logistics and Transportation Review, vol. 90, pp. 177-195, 2016/06/01/ 2016, https://dx.doi.org/10.1016/j.tre.2015.11.010.

[16] M. M. H. Chowdhury and M. A. Quaddus, “A multiple objective optimization based QFD approach for efficient resilient strategies to mitigate supply chain vulnerabilities: The case of garment industry of Bangladesh☆,☆☆☆This manuscript was processed by Associate Editor B. Lev,” Omega, vol. 57, pp. 5-21, 2015/12/01/ 2015, https://dx.doi.org/10.1016/j.omega.2015.05.016.

[17] K. Ganguly Kunal and K. Guin Kalyan, “A fuzzy AHP approach for inbound supply risk assessment,” Benchmarking: An International Journal, vol. 20, no. 1, pp. 129-146, 2013, https://dx.doi.org/10.1108/14635771311299524.

[18] N. Khalil, S. N. Kamaruzzaman, and M. R. Baharum, “Ranking the indicators of building performance and the users’ risk via Analytical Hierarchy Process (AHP): Case of Malaysia,” Ecological Indicators, vol. 71, pp. 567-576, 2016/12/01/ 2016, https://dx.doi.org/10.1016/j.ecolind.2016.07.032.

[19] C. Wan, X. Yan, D. Zhang, Z. Qu, and Z. Yang, “An advanced fuzzy Bayesian-based FMEA approach for assessing maritime supply chain risks,” Transportation Research Part E: Logistics and Transportation Review, vol. 125, pp. 222-240, 2019/05/01/ 2019, https://dx.doi.org/10.1016/j.tre.2019.03.011.

[20] H.-L. Ma and C. Wong Wai-Hung, “A fuzzy-based House of Risk assessment method for manufacturers in global supply chains,” Industrial Management & Data Systems, vol. 118, no. 7, pp. 1463-1476, 2018, https://dx.doi.org/10.1108/IMDS-10-2017-0467.

[21] W. Boonyanusith and P. Jittamai, “Blood Supply Chain Risk Management using House of Risk Model,” Walailak Journal of Science and Technology (WJST), vol. 16, no. 8, pp. 573-591, 01/14 2018, http://wjst.wu.ac.th/index.php/wjst/article/view/3472.

[22] S. Ratnasari, M. Hisjam, and W. Sutopo, “Supply chain risk management in newspaper company: House of risk approach,” 2018, doi: https://dx.doi.org/10.1063/1.5024075.

[23] T. Immawan and D. K. Putri, “House of risk approach for assessing supply chain risk management strategies: A case study in Crumb Rubber Company Ltd,” MATEC Web Conf., vol. 154, p. 01097, 2018. [Online]. Available: https://dx.doi.org/10.1051/matecconf/201815401097.

[24] B. E. Asbjørnslett, “Assessing the Vulnerability of Supply Chains,” Supply Chain Risk: A Handbook of Assessment, Management, and Performance, pp. 15-33, 2009, https://dx.doi.org/10.1007/978-0-387-79934-6_2.

[25] H. M. Wee, M. F. Blos, and W.-H. Yang, “Risk management in logistics,” in Handbook on Decision Making: Springer, 2012, pp. 285-305.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Ahmad Rusdiansyah, Della Deswiana Pratama, Muhammad Faisal Ibrahim

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.