Reduction in Rejection Rate of Soy Sauce Packaging via Six Sigma

DOI:

https://doi.org/10.22219/JTIUMM.Vol22.No1.57-70Keywords:

Six sigma, soy sauce packaging, DMAIC, SOPs, preventive maintenanceAbstract

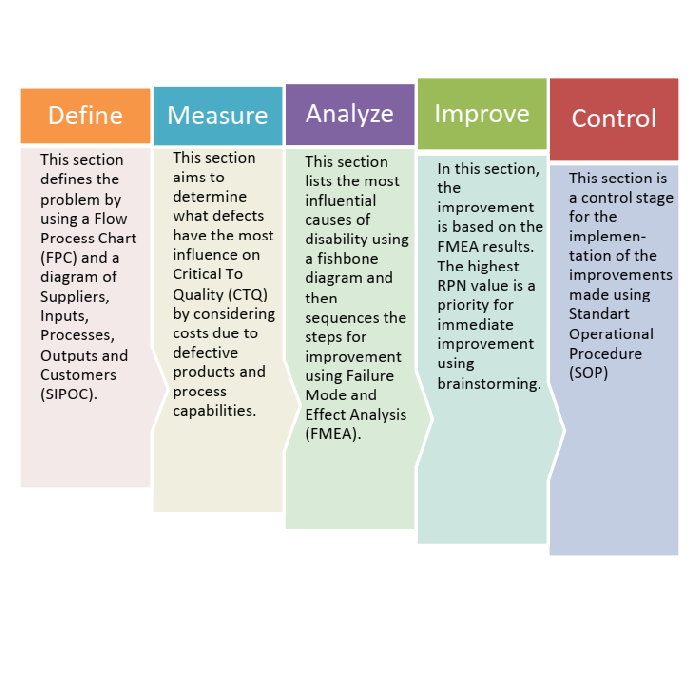

The Six Sigma methodology is the most powerful quality improvement technique. This research deals with applying the Six Sigma methodology in reducing the rejection rate of soy sauce packaging in food production. The DMAIC methodology of Six Sigma provides a step-by-step quality improvement methodology in which statistical techniques are applied. The leakage and cutting error problems were identified in the Define phase. The extent of the problem was measured in the Measure phase. The current DPMO value was 5,794.39, and the sigma level at 4.0245. The root cause of the problem and the improvement priority were identified in the Analyze phase by applying the fishbone diagram and FMEA. The design of new Standard Operating Procedures (SOPs) and preventive maintenance schedule were used in the Improve phase to increase the sigma level by 50-60 percent and decrease DPMO by 99 percent for the upcoming four months implementation. Furthermore, a control plan was provided in the Control phase to monitor and sustain the achieved improvements.

Downloads

References

A. M. Almansur, S. Sukardi, and M. Machfud, "Improving Performance of Biscuit Production Process Through Lean Six-Sigma at PT XYZ," Indonesian Journal of Business and Entrepreneurship (IJBE), vol. 3, p. 77, 2017. https://doi.org/10.17358/ijbe.3.2.77.

A. Kusnadi and G. Yudoko, "Contractor work preparation process improvement using lean six sigma," The South East Asian Journal of Management, vol. 10, pp. 1-29, 2016. https://doi.org/10.21002/seam.v10i1.5781.

J. Hill, A. J. Thomas, R. K. Mason-Jones, and S. El-Kateb, "The implementation of a Lean Six Sigma framework to enhance operational performance in an MRO facility," Production & Manufacturing Research, vol. 6, pp. 26-48, 2018. https://doi.org/10.1080/21693277.2017.1417179.

A. M. H. Pereira, M. R. Silva, M. A. G. Domingues, and J. C. Sá, "Lean Six Sigma Approach to Improve the Production Process in the Mould Industry: a Case Study," Quality Innovation Prosperity, vol. 23, pp. 103-121, 2019. https://doi.org/10.12776/qip.v23i3.1334.

A. Senjuntichai, N. Wonganawat, and B. Thampitakkul, "Defect Reduction in Ready Rice Packaging by Applying Six Sigma," International Journal of Innovation, Management and Technology, vol. 9, pp. 178-183, 2018. https://doi.org/10.18178/ijimt.2018.9.4.810.

Z. He, Y. Deng, M. Zhang, X. Zu, and J. Antony, "An empirical investigation of the relationship between Six Sigma practices and organisational innovation," Total Quality Management & Business Excellence, vol. 28, pp. 459-480, 2017. https://doi.org/10.1080/14783363.2015.1092866.

V. Gaspersz, The Executive Guide To Implementing Lean Six Sigma, 2008.

A. A. Al-Shourah, R. T. Al-Tarawneh, and F. A. Alzu'bi, "The integration of lean management and six sigma strategies to improve the performance of production in industrial pharmaceutical," International Journal of Business and Management, vol. 13, pp. 207-216, 2018. https://doi.org/10.5539/ijbm.v13n8p207.

H. Fransiscus, C. P. Juwono, and I. S. Astari, "Implementasi metode six sigma DMAIC untuk mengurangi paint bucket cacat di PT X," Jurnal Rekayasa Sistem Industri, vol. 3, pp. 53-64, 2014. https://doi.org/10.26593/jrsi.v3i2.1297.53-64.

E. V. Gijo, J. Scaria, and J. Antony, "Application of six sigma methodology to reduce defects of a grinding process," Quality and Reliability Engineering International, vol. 27, pp. 1221-1234, 2011. https://doi.org/10.1002/qre.1212.

H. S. Gitlow, R. J. Melnyck, and D. M. Levine, A guide to Six Sigma and process improvement for practitioners and students: Foundations, DMAIC, Tools, Cases, and Certification, 2 ed.: FT Press, 2015.

S. Indrawati and M. Ridwansyah, "Manufacturing Continuous Improvement Using Lean Six Sigma: An Iron Ores Industry Case Application," Procedia Manufacturing, vol. 4, pp. 528-534, 2015. https://doi.org/10.1016/j.promfg.2015.11.072.

A. Ertas, Transdisciplinary engineering design process: John Wiley & Sons, 2018.

C. T. Carroll, Six Sigma for Powerful Improvement: A Green Belt DMAIC Training System with Software Tools and a 25-Lesson Course: Taylor & Francis, 2013.

V. Gaspersz, "Pedoman implementasi program six sigma terintegrasi dengan ISO 9001: 2000, MBNQA, dan HACCP," PT. Gramedia Pustaka Utama, Jakarta, 2002.

M. Smętkowska and B. Mrugalska, "Using Six Sigma DMAIC to Improve the Quality of the Production Process: A Case Study," Procedia - Social and Behavioral Sciences, vol. 238, pp. 590-596, 2018. https://doi.org/10.1016/j.sbspro.2018.04.039.

V. Gaspersz, The Executive Guide To Implementing Lean Six Sigma: Jakarta: PT. Gramedia Pustaka Utama, 2008.

A. I. L. Deamonita, E. Pujiyanto, and C. N. Rosyidi, "The implementation of lean six sigma in a book manufacturing company: A case study," in AIP Conference Proceedings, 2019, p. 030045. https://doi.org/10.1063/1.5098220.

H. Henny, I. Andriana, A. N. Latifah, and H. Haryanto, "The Application Lean Six Sigma Method Approach to Minimize Waste," in IOP Conference Series: Materials Science and Engineering, 2019, p. 022089. https://doi.org/10.1088/1757-899x/662/2/022089.

M. I. Qureshi, N. Bashir, K. Zaman, N. Sajjad, and S. Fakhr, "Customer Satisfaction Measurement and Analysis Using Six Sigma in Telecom Sector of Pakistan," European Journal of Sustainable Development, vol. 1, pp. 53 - 68, 2012. https://doi.org/10.14207/ejsd.2012.v1n1p53%20-%2068.

A. T. Soemohadiwidjojo, Six Sigma Metode Pengukuran Kinerja Perusahaan Berbasis Statistik: Raih Asa Sukses, 2017.

C. E. Ebeling, An Introduction to Reliability and Maintainability Engineering: Third Edition: Waveland Press, 2019.

S. Andiyanto, A. Sutrisno, and C. C. Punuhsingon, "Penerapan metode FMEA (Failure Mode and Effect Analysis) untuk kuantifikasi dan pencegahan resiko akibat terjadinya lean waste," Jurnal Online Poros Teknik Mesin Unsrat, vol. 6, pp. 45-47, 2017. https://ejournal.unsrat.ac.id/index.php/poros/article/view/14864.

J. Heizer and B. Render, Operations management: sustainability and supply chain management: Pearson Higher Ed, 2013.

R. A. Munro, Lean six Sigma for the healthcare practice: A pocket guide: Quality Press, 2009.

S. O. Parasayu and N. Susanto, Industrial Engineering Online Journal, vol. 5, pp. 1-6, 2016. https://ejournal3.undip.ac.id/index.php/ieoj/article/view/14077.

F. B. Pranata, Business Intelligence Cockpit: Cara Mengukur dan Meningkatkan: Elex Media Komputindo, 2014.

J. G. Rawlinson, Creative Thinking and Brainstorming: Taylor & Francis, 2017.

T. Taufik and S. Septyani, "Penentuan interval waktu perawatan komponen kritis pada mesin turbin di PT PLN (Persero) Sektor Pembangkit Ombilin," jurnal optimasi sistem industri, vol. 14, pp. 238-258, 2016.

A. K. S. Jardine and A. H. C. Tsang, Maintenance, Replacement, and Reliability: Theory and Applications, Second Edition: Taylor & Francis, 2013.

S. Krishna Priya, V. Jayakumar, and S. Suresh Kumar, "Defect analysis and lean six sigma implementation experience in an automotive assembly line," in Materials Today: Proceedings, 2020, pp. 948-958. https://doi.org/10.1016/j.matpr.2019.11.139.

R. Sukwadi, Y. Felicia, and Muaf, "TOC, lean, and six sigma: An integrated model to increase the productivity of the textile industry," Journal of Mechanical Engineering Research & Developments, vol. 44, pp. 327-336, 2021.

J. P. Costa, I. S. Lopes, and J. P. Brito, "Six Sigma application for quality improvement of the pin insertion process," Procedia Manufacturing, vol. 38, pp. 1592-1599, 2019. https://doi.org/10.1016/j.promfg.2020.01.126.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2021 Ronald Sukwadi, Leonardus Harijanto , M.M. Wahyuni Inderawati, Po Tsang B. Huang

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.