Integrated Procurement-Production Inventory Model with Two-Stage Production

DOI:

https://doi.org/10.22219/JTIUMM.Vol21.No2.185-199Keywords:

inventory, Procurement, production, Model, DragonflyAbstract

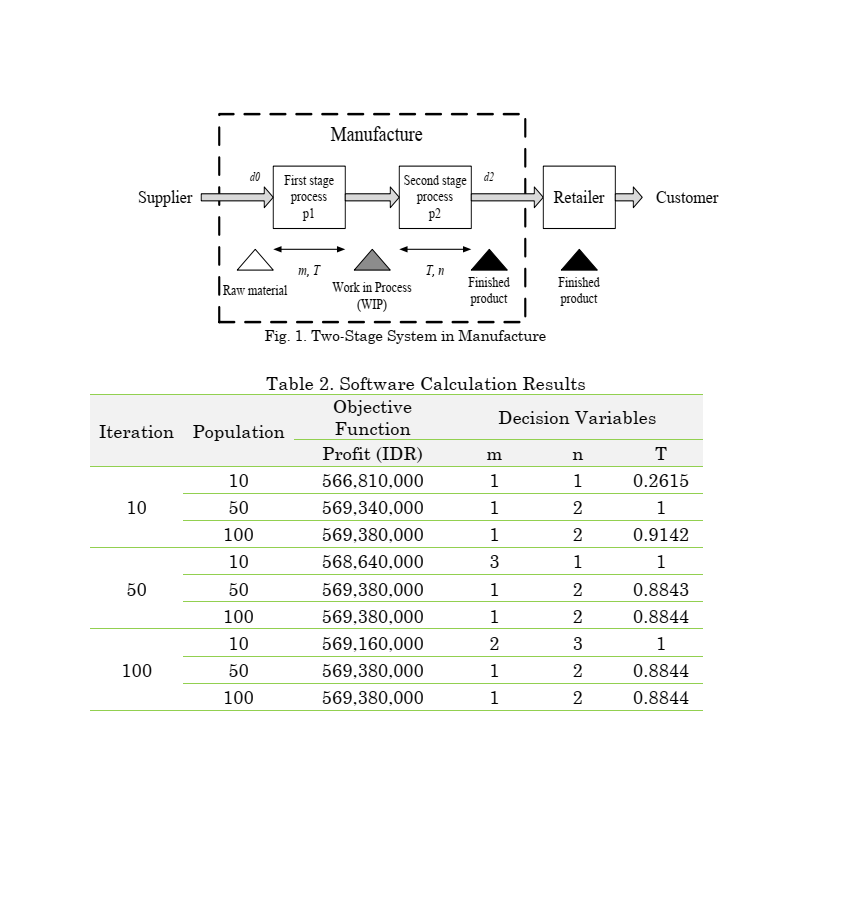

The inventory-production system concerns the effective management of the goods flows from raw materials to finished products. The Integrated Procurement-Production (IPP) system consists of many elements that must be managed effectively. The problem will be more complex if it involves deciding on the number of delivery frequencies at the retailer level. In this case, the Integrated Procurement-Production's objective function depends on the frequency of raw material shipments, the frequency of delivery of finished products, and the production cycle time. This study aims to develop an IPP system to maximize total profit. The decision variables used are the frequency of raw material delivery, the frequency of delivery of finished products, and the production cycle time. This study proposes the Dragonfly Algorithm (DA) as an algorithm for problem-solving. Dragonfly Algorithm is used to find the best inventory decision variables. This study conducted experiments with various iteration parameters and DA population. The results showed that the greater the iteration and the population used, the greater the profit. A sensitivity analysis of decision variables is also presented in this investigation.

Downloads

References

S. Ziukov, "A literature review on models of inventory management under uncertainty," Business Systems & Economics, vol. 5, pp. 26-35 2016. https://doi.org/10.13165/VSE-15-5-1-03.

S. K. Goyal and Y. P. Gupta, "Integrated inventory models: The buyer-vendor coordination," European Journal of Operational Research, vol. 41, pp. 261-269, 1989. https://doi.org/10.1016/0377-2217(89)90247-6.

S. K. D. B. Maulana, D. M. Utama, M. S. Asrofi, I. S. Ningrum, N. Alba, H. A. Ahfa, et al., "The Capacitated Sustainable EOQ Models: Models Considering Tax Emissions," Jurnal Teknik Industri, vol. 21, pp. 12-21, 2019. https://doi.org/10.22219/JTIUMM.Vol21.No1.12-21.

D. M. Utama, "Model Penentuan Lot Pemesanan Dengan Mempertimbangkan Unit Diskon dan Batasan Kapasitas Gudang dengan Program Dinamis," Jurnal Teknik Industri, vol. 18, pp. 94-102, 2017. https://doi.org/10.22219/JTIUMM.Vol18.No1.94-102.

D. M. Utama, D. S. Widodo, M. F. Ibrahim, K. Hidayat, and S. K. Dewi, "The Sustainable Economic Order Quantity Model: A Model Consider Transportation, Warehouse, Emission Carbon Costs, and Capacity Limits," Journal of Physics: Conference Series, vol. 1569, p. 022095, 2020. https://doi.org/10.1088/1742-6596/1569/2/022095.

G. Fauza, Y. Amer, and S.-H. Lee, Model of an integrated procurement-production system for food products incorporating quality loss during storage time vol. 1: IACSIT-Internal Association of Computer Science, 2013. https://doi.org/10.7763/IJMMM.2013.V1.4.

D. M. Utama, D. P. Wardani, S. T. Halifah, and D. C. Pradikta, "Model Economic Production Quantity dengan Rework Process dan Batasan Gudang," Jurnal Sistem dan Manajemen Industri, vol. 3, pp. 43-49, 2019. https://doi.org/10.30656/jsmi.v3i1.1017.

S. K. Goyal, "An Integrated Inventory Model for a Single Product System," Journal of the Operational Research Society, vol. 28, pp. 539-545, 1977. https://doi.org/10.1057/jors.1977.103.

S. K. Goyal and S. G. Deshmukh, "Integrated procurement-production systems: A review," European Journal of Operational Research, vol. 62, pp. 1-10, 1992. https://doi.org/10.1016/0377-2217(92)90172-6.

S. K. Goyal and S. G. Deshmukh, "Integrated procurement- production system in a just-in-time environment-modelling and analysis," Production Planning & Control, vol. 8, pp. 31-36, 1997. https://doi.org/10.1080/095372897235532.

G. Fauza, H. Prasetyo, and B. S. Amanto, "An integrated production-inventory model for food products adopting a general raw material procurement policy," in IOP Conference Series: Materials Science and Engineering, 2018, p. 012013. https://doi.org/10.1088/1757-899x/352/1/012013.

S. Vaziri, A. Zaretalab, M. Esmaeili, and S. T. A. Niaki, "An integrated production and procurement design for a multi-period multi-product manufacturing system with machine assignment and warehouse constraint," Applied Soft Computing, vol. 70, pp. 238-262, 2018. https://doi.org/10.1016/j.asoc.2018.05.037.

S. H. Kim and J. Chandra, "An integrated inventory model for a single product and its raw materials," International Journal of Production Research, vol. 25, pp. 627-634, 1987. https://doi.org/10.1080/00207548708919866.

S. K. Goyal, "Improving the solution of a finite horizon inventory problem under certainty," International Journal of Production Research, vol. 15, pp. 173-178, 1977. https://doi.org/10.1080/00207547708943115.

H. Tarhini, M. Karam, and M. Y. Jaber, "An integrated single-vendor multi-buyer production inventory model with transshipments between buyers," International Journal of Production Economics, vol. 225, p. 107568, 2020. https://doi.org/10.1016/j.ijpe.2019.107568.

M. A. Hoque and S. K. Goyal, "An optimal policy for a single-vendor single-buyer integrated production–inventory system with capacity constraint of the transport equipment," International Journal of Production Economics, vol. 65, pp. 305-315, 2000. https://doi.org/10.1016/S0925-5273(99)00082-1.

C. Yan, A. Banerjee, and L. Yang, "An integrated production–distribution model for a deteriorating inventory item," International Journal of Production Economics, vol. 133, pp. 228-232, 2011. https://doi.org/10.1016/j.ijpe.2010.04.025.

X. Liu, W. Wang, and R. Peng, "An integrated production, inventory and preventive maintenance model for a multi-product production system," Reliability Engineering & System Safety, vol. 137, pp. 76-86, 2015. https://doi.org/10.1016/j.ress.2015.01.002.

G. Fauza, Y. Amer, S.-H. Lee, and H. Prasetyo, "An integrated single-vendor multi-buyer production-inventory policy for food products incorporating quality degradation," International Journal of Production Economics, vol. 182, pp. 409-417, 2016. https://doi.org/10.1016/j.ijpe.2016.09.009.

G. Fauza, Y. Amer, S. H. Lee, and H. Prasetyo, "An inventory model of production-inventory policy for food products considering quality loss in raw materials," in 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), 2015, pp. 910-914. https://doi.org/10.1109/IEEM.2015.7385780.

M. Pourakbar, R. Z. Farahani, and N. Asgari, "A joint economic lot-size model for an integrated supply network using genetic algorithm," Applied Mathematics and Computation, vol. 189, pp. 583-596, 2007. https://doi.org/10.1016/j.amc.2006.11.116.

G. Fauza, H. Prasetyo, and B. S. Amanto, "Development of an integrated production-inventory model for food products considering exponential perceived value loss," IOP Conference Series: Materials Science and Engineering, vol. 403, p. 012050, 2018. https://doi.org/10.1088/1757-899x/403/1/012050.

K. Sarrafha, S. H. A. Rahmati, S. T. A. Niaki, and A. Zaretalab, "A bi-objective integrated procurement, production, and distribution problem of a multi-echelon supply chain network design: A new tuned MOEA," Computers & Operations Research, vol. 54, pp. 35-51, 2015. https://doi.org/10.1016/j.cor.2014.08.010.

A. C. Leuveano, F. A. B. Jafar, and M. R. B. Muhamad, "Development of genetic algorithm on multi-vendor integrated procurement-production system under shared transportation and just-in-time delivery system," in 2012 2nd International Conference on Uncertainty Reasoning and Knowledge Engineering, 2012, pp. 78-81. https://doi.org/10.1109/URKE.2012.6319589.

S. K. Goyal, S. G. Deshmukh, and A. S. Babu, "A Model for Integrated Procurement-Production Systems," Journal of the Operational Research Society, vol. 41, pp. 1029-1035, 1990. https://doi.org/10.1057/jors.1990.161.

F. Raafat, "A production-inventory model for decaying raw materials and a decaying single finished product system," International Journal of Systems Science, vol. 16, pp. 1039-1044, 1985. https://doi.org/10.1080/00207728508926731.

P.-C. Yang and H.-M. Wee, "Economic ordering policy of deteriorated item for vendor and buyer: An integrated approach," Production Planning & Control, vol. 11, pp. 474-480, 2000. https://doi.org/10.1080/09537280050051979.

S. Mirjalili, "Dragonfly algorithm: a new meta-heuristic optimization technique for solving single-objective, discrete, and multi-objective problems," Neural Computing and Applications, vol. 27, pp. 1053-1073, 2016. https://doi.org/10.1007/s00521-015-1920-1.

G. Fauza, H. Prasetyo, N. K. Dania, and B. S. Amanto, "Development of food inventory model in an integrated vendor-buyer system: Case study in food industry," AIP Conference Proceedings, vol. 1977, p. 020053, 2018. https://doi.org/10.1063/1.5042909.

S. Mirjalili and A. Lewis, "S-shaped versus V-shaped transfer functions for binary Particle Swarm Optimization," Swarm and Evolutionary Computation, vol. 9, pp. 1-14, 2013. https://doi.org/10.1016/j.swevo.2012.09.002.

C. Shilaja and K. Ravi, "Optimal Power Flow Using Hybrid DA-APSO Algorithm in Renewable Energy Resources," Energy Procedia, vol. 117, pp. 1085-1092, 2017. https://doi.org/10.1016/j.egypro.2017.05.232.

M. A. Salam, H. M. Zawbaa, E. Emary, K. K. A. Ghany, and B. Parv, "A hybrid dragonfly algorithm with extreme learning machine for prediction," in 2016 International Symposium on INnovations in Intelligent SysTems and Applications (INISTA), 2016, pp. 1-6. https://doi.org/10.1109/INISTA.2016.7571839.

A. N. M. Nagib, A. N. Adnan, A. Ismail, N. H. A. Halim, and N. S. Khusaini, "The Role of Hybrid Make-to-Stock (MTS) - Make-to-Order (MTO) and Economic Order Quantity (EOQ) Inventory Control Models in Food and Beverage Processing Industry," in IOP Conference Series: Materials Science and Engineering, 2016, p. 012003. https://doi.org/10.1088/1757-899x/160/1/012003.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Dana Marsetiya Utama, Heri Mujayin Kholik, Azis Fredy Mulya

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.