Reduce Waste using Integration of Lean Six Sigma and TRIZ Method: A Case Study in Wood Industry

DOI:

https://doi.org/10.22219/JTIUMM.Vol21.No2.139-152Keywords:

waste, lean, six sigma, lean manufacturing, TRIZAbstract

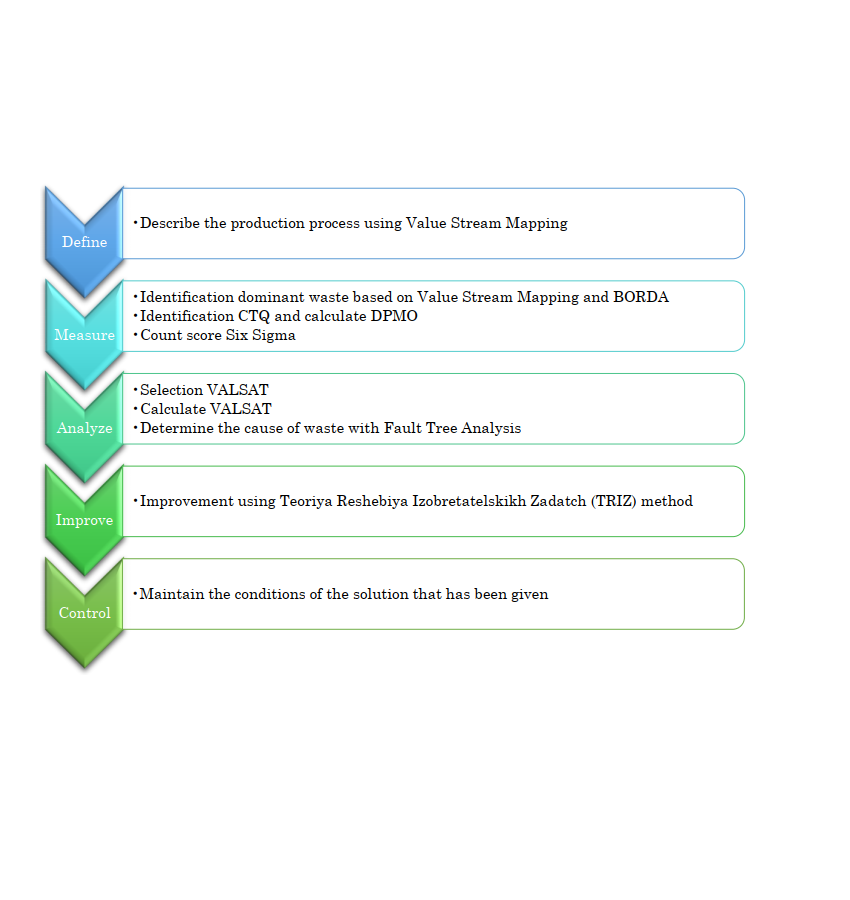

Recently, lean production has become a major focus of researchers and industry. The zero-waste concept holds an important role in the production process. The aim of this concept is to reduce waste and increase productivity. Wastes have significant negative impacts on the company, one of which is the decrease of company profit. This research aimed to integrate the Lean Six Sigma method with Teorya Resheniya Izobreatatelskikh Zadatch (TRIZ) in order to reduce wastes. These two methods were applied with Define-Measure-Analyze-Improve-Control(DMAIC) methodology. A case study was conducted in a wood manufacturing company. The results of the study suggest that the application of the two methods can significantly reduce the Non-value Added (NVA).

Downloads

References

A. Cherrafi, S. Elfezazi, K. Govindan, J. A. Garza-Reyes, K. Benhida, and A. Mokhlis, "A framework for the integration of Green and Lean Six Sigma for superior sustainability performance," International Journal of Production Research, vol. 55, pp. 4481-4515, 2017. https://doi.org/10.1080/00207543.2016.1266406.

D. M. Utama, S. K. Dewi, and V. I. Mawarti, "Identifikasi waste pada proses produksi key set clarinet dengan pendekatan lean manufacturing," Jurnal Ilmiah Teknik Industri, vol. 15, pp. 36-46, 2016. https://doi.org/10.23917/jiti.v15i1.1572.

A. M. Deif, "A system model for green manufacturing," Journal of Cleaner Production, vol. 19, pp. 1553-1559, 2011. https://doi.org/10.1016/j.jclepro.2011.05.022.

H. S. Sodhi, B. J. Singh, and D. Singh, "A conceptual examination of Lean, Six Sigma and Lean Six Sigma models for managing waste in manufacturing SMEs," World Journal of Science, Technology and Sustainable Development, vol. 17, pp. 20-32, 2020. https://doi.org/10.1108/WJSTSD-10-2019-0073.

H. B. Ismail and Z. B. M. Yusof, "Understanding Defects During the Construction Process," Advanced Science Letters, vol. 24, pp. 4227-4231, 2018.

A. Karim and M. Islam, "Manufacturing practices and performance," International Journal of Quality & Reliability Management, vol. 28, pp. 43-61, 2011. https://doi.org/10.1108/02656711111097544.

J. Maleyeff and E. D. Arnheiter, "The integration of lean management and Six Sigma," The TQM Magazine, vol. 17, pp. 5-18, 2005. https://doi.org/10.1108/09544780510573020.

E. Amrina and A. A. A. Lubis, "Minimizing waste using lean manufacturing: A case in cement production," in 2017 4th International Conference on Industrial Engineering and Applications (ICIEA), 2017, pp. 71-75. https://doi.org/10.1109/IEA.2017.7939181.

M. De la Vega-Rodríguez, Y. A. Baez-Lopez, D.-L. Flores, D. A. Tlapa, and A. Alvarado-Iniesta, "Lean Manufacturing: A Strategy for Waste Reduction," in New Perspectives on Applied Industrial Tools and Techniques, J. L. García-Alcaraz, G. Alor-Hernández, A. A. Maldonado-Macías, and C. Sánchez-Ramírez, Eds., ed Cham: Springer International Publishing, 2018, pp. 153-174. https://doi.org/10.1007/978-3-319-56871-3_8.

N. A. A. Rahman, S. M. Sharif, and M. M. Esa, "Lean manufacturing case study with Kanban system implementation," Procedia Economics and Finance, vol. 7, pp. 174-180, 2013. https://doi.org/10.1016/S2212-5671(13)00232-3.

D. Romero, P. Gaiardelli, D. Powell, T. Wuest, and M. Thürer, "Digital Lean Cyber-Physical Production Systems: The Emergence of Digital Lean Manufacturing and the Significance of Digital Waste," in Advances in Production Management Systems. Production Management for Data-Driven, Intelligent, Collaborative, and Sustainable Manufacturing, Cham, 2018, pp. 11-20. https://doi.org/10.1007/978-3-319-99704-9_2.

C. Bai, A. Satir, and J. Sarkis, "Investing in lean manufacturing practices: an environmental and operational perspective," International Journal of Production Research, vol. 57, pp. 1037-1051, 2019. https://doi.org/10.1080/00207543.2018.1498986.

M. Ade and V. Deshpande, "Lean manufacturing and productivity improvement in coal mining industry," International Journal of Engineering Research and Development, vol. 2, pp. 35-43, 2012.

R. Trehan, A. Gupta, and M. Handa, "Implementation of Lean Six Sigma framework in a large scale industry: a case study," International Journal of Six Sigma and Competitive Advantage, vol. 11, pp. 23-41, 2019. https://doi.org/10.1504/IJSSCA.2019.098710.

J. Antony, D. A. Desai, and M. B. Patel, "An assessment of the critical success factors for Six Sigma implementation in Indian industries," International Journal of Productivity and Performance Management, vol. 61, pp. 426-444, 2012. https://doi.org/10.1108/17410401211212670.

A. Sulaksmi, "Penerapan Lean Sigma untuk Menggurangi Waste pada Produksi Benih Jagung," Jurnal Teknik Industri, vol. 8, pp. 88-98, 2008. https://doi.org/10.22219/JTIUMM.Vol8.No1.88-98.

J. Ochieng, J. Douglas, and A. Douglas, "Lean Six Sigma implementation in East Africa: findings from a pilot study," The TQM Journal, vol. 27, pp. 772-780, 2015. https://doi.org/10.1108/TQM-05-2015-0066.

A. Sohal and R. J. Hilton, "A conceptual model for the successful deployment of Lean Six Sigma," International Journal of Quality & Reliability Management, vol. 29, pp. 54-70, 2012. https://doi.org/10.1108/02656711211190873.

A. J. Thomas, M. Francis, R. Fisher, and P. Byard, "Implementing Lean Six Sigma to overcome the production challenges in an aerospace company," Production Planning & Control, vol. 27, pp. 591-603, 2016. https://doi.org/10.1080/09537287.2016.1165300.

D. Micu, "Six Sigma: tools and methodology for the clothing industry," in Proceedings of The 6th International Management Conference Approaches In Organizational Management, Bucharest, 2012, pp. 505-510.

P. Manfredsson, O.-P. Hilmola, P. Hilletofth, and R. Andersson, "Lean Six Sigma strategy in telecom manufacturing," Industrial Management & Data Systems, vol. 114, pp. 904-921, 2014. https://doi.org/10.1108/IMDS-02-2014-0069.

I. Belekoukias, J. A. Garza-Reyes, and V. Kumar, "The impact of lean methods and tools on the operational performance of manufacturing organisations," International Journal of production research, vol. 52, pp. 5346-5366, 2014. https://doi.org/10.1080/00207543.2014.903348.

A. Chiarini, "Risk management and cost reduction of cancer drugs using Lean Six Sigma tools," Leadership in Health Services, vol. 25, pp. 318-330, 2012. https://doi.org/10.1108/17511871211268982.

A. Chiarini and E. Bracci, "Implementing Lean Six Sigma in healthcare: issues from Italy," Public Money & Management, vol. 33, pp. 361-368, 2013. https://doi.org/10.1080/09540962.2013.817126.

A. Soti, R. Shankar, and O. P. Kaushal, "Six Sigma with innovation tool kit of TRIZ," International Journal of Business Innovation and Research, vol. 6, pp. 220-237, 2012. https://doi.org/10.1504/IJBIR.2012.045638.

L. B. M. Costa, M. Godinho Filho, L. D. Fredendall, and G. M. Devós Ganga, "Lean six sigma in the food industry: Construct development and measurement validation," International Journal of Production Economics, vol. 231, p. 107843, 2021. https://doi.org/10.1016/j.ijpe.2020.107843.

F. Nabhani, S. Bala, G. Evans, and A. Shokri, "Review of implementing lean six sigma to reduce environmental wastes of internal supply chains in food industry," in 15th international conference on manufacturing research, ICMR 2017, 2017, pp. 327-332.

L. Chechurin, "TRIZ in science. Reviewing indexed publications," Procedia CIRP, vol. 39, pp. 156-165, 2016. https://doi.org/10.1016/j.procir.2016.01.182.

D. Nallusamy, R. Nivedha, E. Subash, V. Venkadesh, S. Vignesh, and P. kumar, "Minimization of Rejection Rate using Lean Six Sigma Tool in Medium Scale Manufacturing Industry," International Journal of Mechanical Engineering and Technology, vol. 9, pp. 1184-1194, 2018.

D. Black, "Partial justification of the Borda count," Public Choice, vol. 28, pp. 1-15, 1976. https://doi.org/10.1007/BF01718454.

A. R. Singh, V. Swarnakar, and A. K. Tiwari, "Evaluating the effect of critical failure factors associated with sustainable Lean Six Sigma framework implementation in healthcare organization," International Journal of Quality & Reliability Management, vol. ahead-of-print, 2020. https://doi.org/10.1108/IJQRM-07-2020-0243.

A. Coskun, W. P. Oosterhuis, M. Serteser, and I. Unsal, "Sigma metric or defects per million opportunities (DPMO): the performance of clinical laboratories should be evaluated by the Sigma metrics at decimal level with DPMOs," Clinical Chemistry and Laboratory Medicine (CCLM), vol. 54, pp. e217-e219, 2016. https://doi.org/10.1515/cclm-2015-1219.

P. Hines and N. Rich, "The seven value stream mapping tools," International Journal of Operations & Production Management, vol. 17, pp. 46-64, 1997. https://doi.org/10.1108/01443579710157989.

S. Kabir, "An overview of fault tree analysis and its application in model based dependability analysis," Expert Systems with Applications, vol. 77, pp. 114-135, 2017. https://doi.org/10.1016/j.eswa.2017.01.058.

D. Cavallucci, TRIZ–The Theory of Inventive Problem Solving: Current Research and Trends in French Academic Institutions vol. 1: Springer, 2017. https://doi.org/10.1007/978-3-319-56593-4.

P. Tsarouhas, "Statistical analysis of failure data for estimating reliability, availability and maintainability of an automated croissant production line," Journal of Quality in Maintenance Engineering, vol. 25, pp. 452-475, 2019. https://doi.org/10.1108/JQME-04-2018-0029.

B. S. Kothavale, S. G. Joshi, L. Y. Waghmode, and R. B. Patil, "Reliability analysis of CNC turning center based on the assessment of trends in maintenance data," International Journal of Quality & Reliability Management, vol. 34, pp. 1616-1638, 2017. https://doi.org/10.1108/IJQRM-08-2016-0126.

I. Q. Alsaffar and H. S. Ketan, "Integrating of Lean Six Sigma methodology and ergonomics principles for improvement in an assembly industrial workstation," Journal of Engineering, vol. 25, pp. 12-29, 2019. https://doi.org/10.31026/j.eng.2019.09.2.

J.-M. Barragan-Ferrer, S. Negny, J. Damasius, D. Barragan-Ferrer, and D. Cizeikiene, "TRIZ evolution trends as an approach for predicting the future development of the technological systems in the food industry," in Managing Innovation in Highly Restrictive Environments, ed: Springer, 2019, pp. 247-277. https://doi.org/10.1007/978-3-319-93716-8_12.

L. Gaikwad, V. Sunnapwar, and S. N. Teli, "Adaption of TRIZ method for problem solving: a case study," International Journal of Six Sigma and Competitive Advantage, vol. 10, pp. 146-155, 2016. https://doi.org/10.1504/IJSSCA.2016.080804.

F. Z. Ben Moussa, I. Rasovska, S. Dubois, R. De Guio, and R. Benmoussa, "Reviewing the use of the theory of inventive problem solving (TRIZ) in green supply chain problems," Journal of Cleaner Production, vol. 142, pp. 2677-2692, 2017. https://doi.org/10.1016/j.jclepro.2016.11.008.

S. L. Furterer, Lean Six Sigma in service: applications and case studies: CRC press, 2016.

B. J. Galli and M. A. Kaviani, "The impacts of risk on deploying and sustaining Lean Six Sigma initiatives," International Journal of Risk and Contingency Management (IJRCM), vol. 7, pp. 46-70, 2018. http://doi.org/10.4018/IJRCM.2018010104.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Dian Hadi Purnomo, Muhammad Lukman

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.