The Determination of Preventive Maintenance using Simulated Annealing Algorithm based on Weighted Fitness Function

DOI:

https://doi.org/10.22219/JTIUMM.Vol20.No1.53-61Keywords:

Simulated annealing algorithm, Fitness function, preventive maintenance, Weibull Distribution, Failure time dataAbstract

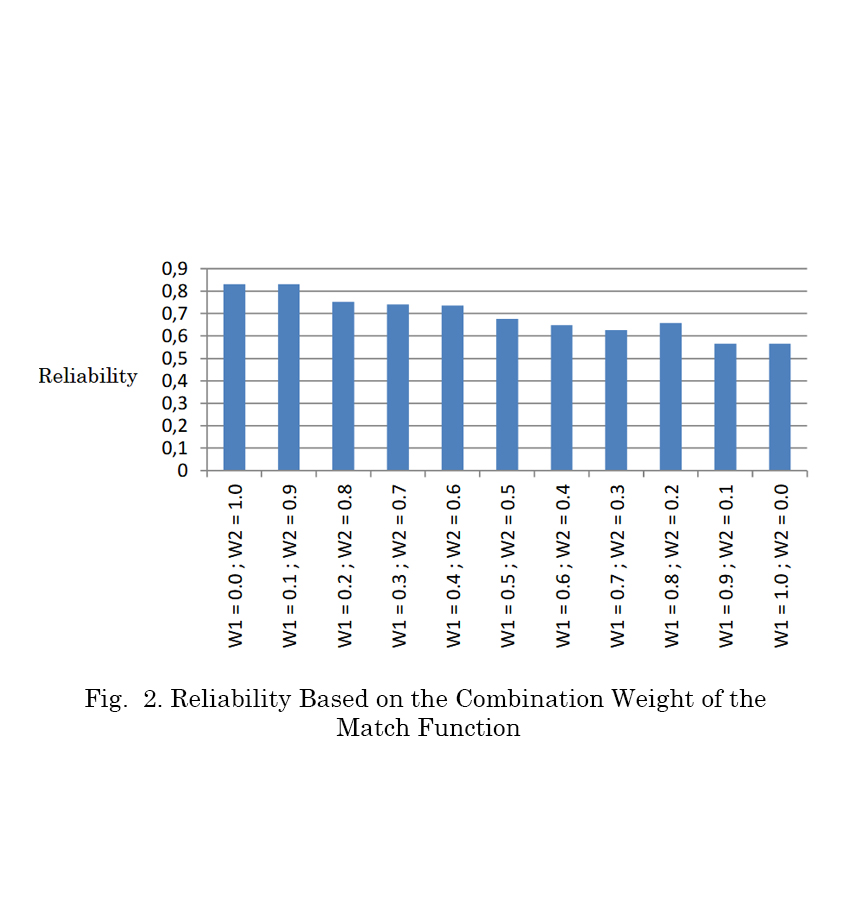

This study aims to determine the machine maintenance schedule. We use the Simulated Annealing Algorithm. Fitness and reliability functions are functions that are used in the optimization process. Several weighting scenarios are done to see the unity of the function. The results of the scenario produce several alternative schedules. This algorithm is implemented on machines that have more than one sub-machine. This sub-machine is a smaller engine system part. This sub-machine also has one particular function. The results of the study show that the optimal engine maintenance period to use is six periods. There are five scheduling scenarios used in this problem. The resulting schedule can increase the value of reliability and can minimize costs.

Downloads

References

[1] E. Pan, G. Wang, L. Xi, L. Chen, and X. Han, "Single-machine group scheduling problem considering learning, forgetting effects and preventive maintenance," International Journal of Production Research, vol. 52, pp. 5690-5704, 2014. https://doi.org/10.1080/00207543.2014.904967.

[2] T. Chen, J. Li, P. Jin, and G. Cai, "Reusable rocket engine preventive maintenance scheduling using genetic algorithm," Reliability Engineering & System Safety, vol. 114, pp. 52-60, 2013. https://doi.org/10.1016/j.ress.2012.12.020.

[3] N. Ayoobian and M. Mohsendokht, "Multi-objective optimization of maintenance programs in nuclear power plants using Genetic Algorithm and Sensitivity Index decision making," Annals of Nuclear Energy, vol. 88, pp. 95-99, 2016. https://doi.org/10.1016/j.anucene.2015.10.033.

[4] F. Moinian, H. Sabouhi, J. Hushmand, A. Hallaj, H. Khaledi, and M. Mohammadpour, "Gas turbine preventive maintenance optimization using genetic algorithm," International Journal of System Assurance Engineering and Management, vol. 8, pp. 594-601, 2017. https://doi.org/10.1007/s13198-017-0627-3.

[5] A. H. Shirmohammadi, Z. G. Zhang, and E. Love, "A Computational Model for Determining the Optimal Preventive Maintenance Policy With Random Breakdowns and Imperfect Repairs," IEEE Transactions on Reliability, vol. 56, pp. 332-339, 2007. https://doi.org/10.1109/TR.2007.896747.

[6] K. S. Moghaddam, "Preventive maintenance and replacement scheduling: models and algorithms," Doctoral Dissertation, Industrial Engineering, University of Louisville, 2010. https://doi.org/10.18297/etd/994.

[7] H. Allaoui and A. Artiba, "Integrating simulation and optimization to schedule a hybrid flow shop with maintenance constraints," Computers & Industrial Engineering, vol. 47, pp. 431-450, 2004. https://doi.org/10.1016/j.cie.2004.09.002.

[8] P. K. Nguyen, T. G. Crainic, and M. Toulouse, "A hybrid generational genetic algorithm for the periodic vehicle routing problem with time windows," Journal of Heuristics, vol. 20, pp. 383-416, 2014. https://doi.org/10.1007/s10732-014-9244-3.

[9] A. Azadeh, M. H. Farahani, H. Eivazy, S. Nazari-Shirkouhi, and G. Asadipour, "A hybrid meta-heuristic algorithm for optimization of crew scheduling," Applied Soft Computing, vol. 13, pp. 158-164, 2013. https://doi.org/10.1016/j.asoc.2012.08.012.

[10] Z. Pooranian, M. Shojafar, R. Tavoli, M. Singhal, and A. Abraham, "Hybrid metaheuristic algorithm for job scheduling on computational grids," Informatica, vol. 37, 2013. www.informatica.si/index.php/informatica/article/viewFile/445/449.

[11] S. Allahyari, M. Salari, and D. Vigo, "A hybrid metaheuristic algorithm for the multi-depot covering tour vehicle routing problem," European Journal of Operational Research, vol. 242, pp. 756-768, 2015. https://doi.org/10.1016/j.ejor.2014.10.048.

[12] S. Q. Liu and E. Kozan, "A hybrid metaheuristic algorithm to optimise a real-world robotic cell," Computers & Operations Research, vol. 84, pp. 188-194, 2017. https://doi.org/10.1016/j.cor.2016.09.011.

[13] A. N. K. Nasir, R. M. T. Raja Ismail, and M. O. Tokhi, "Adaptive spiral dynamics metaheuristic algorithm for global optimisation with application to modelling of a flexible system," Applied Mathematical Modelling, vol. 40, pp. 5442-5461, 2016. https://doi.org/10.1016/j.apm.2016.01.002.

[14] B. Vahedi Nouri, P. Fattahi, and R. Ramezanian, "Hybrid firefly-simulated annealing algorithm for the flow shop problem with learning effects and flexible maintenance activities," International Journal of Production Research, vol. 51, pp. 3501-3515, 2013. https://doi.org/10.1080/00207543.2012.750771.

[15] Y. Wang, G. Bu, Y. Wang, T. Zhao, Z. Zhang, and Z. Zhu, "Application of a simulated annealing algorithm to design and optimize a pressure-swing distillation process," Computers & Chemical Engineering, vol. 95, pp. 97-107, 2016. https://doi.org/10.1016/j.compchemeng.2016.09.014.

[16] L. Kang and X. Zhu, "A simulated annealing algorithm for first train transfer problem in urban railway networks," Applied Mathematical Modelling, vol. 40, pp. 419-435, 2016. https://doi.org/10.1016/j.apm.2015.05.008.

[17] H. Zhang, N. Li, W. Zhang, and X. Pei, "Experiments to automatically monitor drought variation using simulated annealing algorithm," Natural Hazards, vol. 84, pp. 175-184, 2016. https://doi.org/10.1007/s11069-016-2414-x.

[18] I. Jerin Leno, S. Saravana Sankar, and S. G. Ponnambalam, "An elitist strategy genetic algorithm using simulated annealing algorithm as local search for facility layout design," The International Journal of Advanced Manufacturing Technology, vol. 84, pp. 787-799, 2016. https://doi.org/10.1007/s00170-013-5519-3.

[19] W. Kuo, V. R. Prasad, F. A. Tillman, and C.-L. Hwang, Optimal reliability design: fundamentals and applications: Cambridge university press, 2001. http://sutlib2.sut.ac.th/sut_contents/H113121.pdf.

[20] G. Giovani, "Optimization of preventive maintenance scheduling using genetic Algorithm," Bachelor Program, Department of Statistics, Universitas Padjadjaran, Bandung, 2018.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Yeny Krista Franty, Budhi Handoko

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.