An Effective Hybrid Sine Cosine Algorithm to Minimize Carbon Emission on Flow-shop Scheduling Sequence Dependent Setup

DOI:

https://doi.org/10.22219/JTIUMM.Vol20.No1.62-72Keywords:

Emissions, Sine Cosine, flow shop, SchedulingAbstract

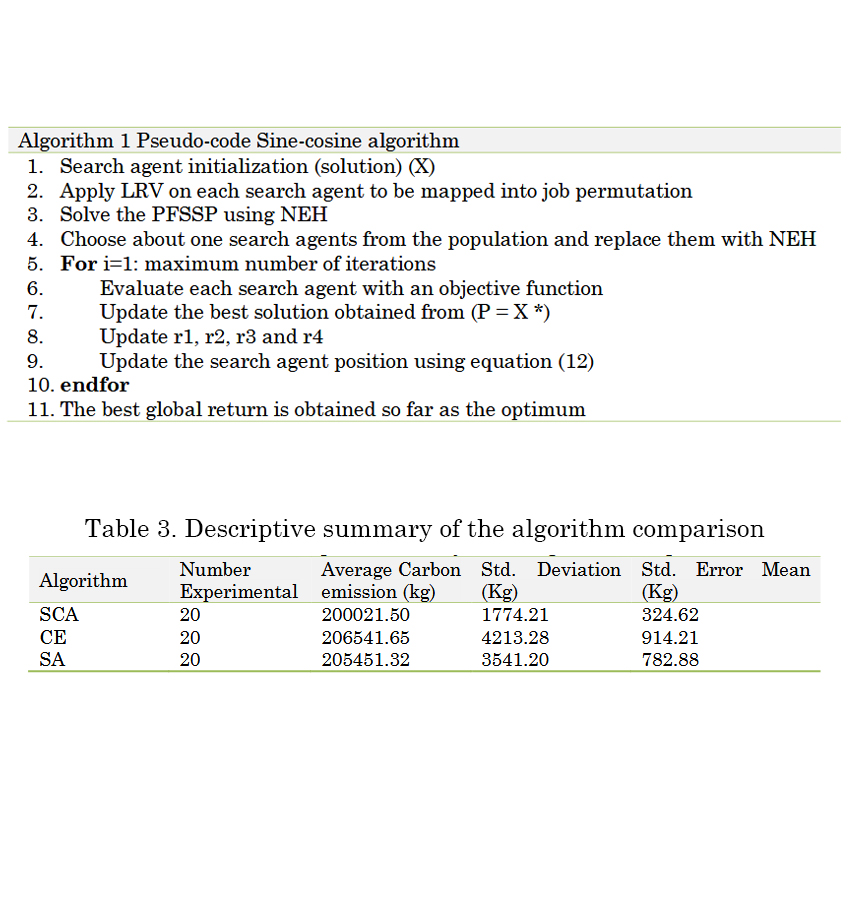

Recently, carbon emissions have become a major environmental problem. In the industrial sector, carbon emissions account for half of the world's total carbon emissions. This article discusses the issue of scheduling Flow Shop Sequence Dependent Setup (FSSDS). It aims to minimize carbon emissions. The algorithm proposed is the Hybrid Sine Cosine Algorithm (HSCA) to solve FSSDS problems to reduce carbon emissions. We offered one of some search agents in the SCA using NEH. The algorithm is used for some tests on different jobs and machines. Several experiments were carried out to test the parameters and effectiveness of the algorithm. The parameters used in the trial are population and iteration. As a result, several parameters were proposed to HSCA to minimize carbon emissions. In the effectiveness test, the HSCA showed better performance compared to the simulated annealing and cross-entropy algorithm.

Downloads

References

[1] S. Shafiee and E. Topal, "When will fossil fuel reserves be diminished?," Energy Policy, vol. 37, pp. 181-189, 2009. https://doi.org/10.1016/j.enpol.2008.08.016.

[2] K. Aleklett, M. Höök, K. Jakobsson, M. Lardelli, S. Snowden, and B. Söderbergh, "The Peak of the Oil Age – Analyzing the world oil production Reference Scenario in World Energy Outlook 2008," Energy Policy, vol. 38, pp. 1398-1414, 2010. https://doi.org/10.1016/j.enpol.2009.11.021.

[3] T. Simunic, L. Benini, and G. D. Micheli, "Energy-efficient design of battery-powered embedded systems," IEEE Transactions on Very Large Scale Integration (VLSI) Systems, vol. 9, pp. 15-28, 2001. https://doi.org/10.1109/92.920814.

[4] V. Swaminathan and K. Chakrabarty, "Energy-conscious, deterministic I/O device scheduling in hard real-time systems," IEEE Transactions on Computer-Aided Design of Integrated Circuits and Systems, vol. 22, pp. 847-858, 2003. https://doi.org/10.1109/TCAD.2003.814245.

[5] T. Gutowski, C. Murphy, D. Allen, D. Bauer, B. Bras, T. Piwonka, et al., "Environmentally benign manufacturing: Observations from Japan, Europe and the United States," Journal of Cleaner Production, vol. 13, pp. 1-17, 2005. https://doi.org/10.1016/j.jclepro.2003.10.004.

[6] S. Harto, A. K. Garside, and D. M. Utama, "Penjadwalan Produksi Menggunakan Algoritma Jadwal Non Delay Untuk Meminimalkan Makespan (studi kasus di CV. Bima Mebel)," Spektrum Industri, vol. 14, pp. 79-88, 2015. http://journal.uad.ac.id/index.php/Spektrum/article/view/3706.

[7] D. M. Utama, "Analisa Perbandingan Penggunaan Aturan Prioritas Penjadwalan Pada Penjadwalan Non Delay N Job 5 Machine," Prosiding SENTRA (Seminar Teknologi dan Rekayasa), vol. 2, pp. 19-23, 2017. http://research-report.umm.ac.id/index.php/research-report/article/view/1180.

[8] I. Masudin, D. M. Utama, and F. Susastro, "Penjadwalan Flowshop Menggunakan Algoritma Nawaz Enscore Ham," Jurnal Ilmiah Teknik Industri, vol. 13, pp. 54-59, 2014. https://doi.org/10.23917/jiti.v13i1.321.

[9] I. Benkalai, D. Rebaine, C. Gagné, and P. Baptiste, "The migrating birds optimization metaheuristic for the permutation flow shop with sequence dependent setup times," IFAC-PapersOnLine, vol. 49, pp. 408-413, 2016. https://doi.org/10.1016/j.ifacol.2016.07.640.

[10] H. G. Campbell, R. A. Dudek, and M. L. Smith, "A heuristic algorithm for the n job, m machine sequencing problem," Management science, vol. 16, pp. B-630-B-637, 1970. https://doi.org/10.1287/mnsc.16.10.B630.

[11] D. M. Utama, "Algoritma LPT-Branch and Bound Pada Penjadwalan Flexible Flowshop untuk Meminimasi Makespan," PROZIMA (Productivity, Optimization and Manufacturing System Engineering), vol. 2, pp. 20-26, 2018. http://ojs.umsida.ac.id/index.php/prozima/article/view/1527.

[12] M. Nawaz, E. E. Enscore, and I. Ham, "A heuristic algorithm for the m-machine, n-job flow-shop sequencing problem," Omega, vol. 11, pp. 91-95, 1983. https://doi.org/10.1016/0305-0483(83)90088-9.

[13] M. Husen, I. Masudin, and D. Utama, "Penjadwalan job shop statik dengan metode simulated annealing untuk meminimasi waktu makespan," Spektrum Industri, vol. 13, pp. 115-228, 2015. http://dx.doi.org/10.12928/si.v13i2.2689.

[14] M. Firdaus, I. Masudin, and D. M. Utama, "Penjadwalan Flowshop Dengan Menggunakan Simulated Annealing," Spektrum Industri, vol. 13, pp. 27-40, 2015. http://dx.doi.org/10.12928/si.v13i1.1836.

[15] R. Nasution, A. K. Garside, and D. M. Utama, "Penjadwalan Job Shop Dengan Pendekatan Algoritma Artificial Immune System," Jurnal Teknik Industri, vol. 18, pp. 29-42, 2017. https://doi.org/10.22219/JTIUMM.Vol18.No1.29-42.

[16] V. Riahi, M. A. H. Newton, K. Su, and A. Sattar, "Constraint guided accelerated search for mixed blocking permutation flowshop scheduling," Computers & Operations Research, vol. 102, pp. 102-120, 2019. https://doi.org/10.1016/j.cor.2018.10.003.

[17] C.-Y. Cheng, K.-C. Ying, H.-H. Chen, and J.-X. Lin, "Optimization algorithms for proportionate flowshop scheduling problems with variable maintenance activities," Computers & Industrial Engineering, vol. 117, pp. 164-170, 2018. https://doi.org/10.1016/j.cie.2018.01.027.

[18] V. Riahi, M. Khorramizadeh, M. A. Hakim Newton, and A. Sattar, "Scatter search for mixed blocking flowshop scheduling," Expert Systems with Applications, vol. 79, pp. 20-32, 2017. https://doi.org/10.1016/j.eswa.2017.02.027.

[19] N. Karimi and H. Davoudpour, "Multi-objective colonial competitive algorithm for hybrid flowshop problem," Applied Soft Computing, vol. 49, pp. 725-733, 2016. https://doi.org/10.1016/j.asoc.2016.06.034.

[20] S. Hatami, L. Calvet, V. Fernández-Viagas, J. M. Framiñán, and A. A. Juan, "A simheuristic algorithm to set up starting times in the stochastic parallel flowshop problem," Simulation Modelling Practice and Theory, vol. 86, pp. 55-71, 2018. https://doi.org/10.1016/j.simpat.2018.04.005.

[21] D. M. Utama, "Pengembangan Algoritma NEH Dan CDS Untuk Meminimasi Consumption Energy Pada Penjadwalan Flow Shop," Prosiding SENTRA (Seminar Teknologi dan Rekayasa), vol. 4, pp. 47-54, 2018. http://research-report.umm.ac.id/index.php/sentra/article/view/2309.

[22] Q. Liu, M. Zhan, F. O. Chekem, X. Shao, B. Ying, and J. W. Sutherland, "A hybrid fruit fly algorithm for solving flexible job-shop scheduling to reduce manufacturing carbon footprint," Journal of Cleaner Production, vol. 168, pp. 668-678, 2017. https://doi.org/10.1016/j.jclepro.2017.09.037.

[23] Z. Zeng, M. Hong, Y. Man, J. Li, Y. Zhang, and H. Liu, "Multi-object optimization of flexible flow shop scheduling with batch process — Consideration total electricity consumption and material wastage," Journal of Cleaner Production, vol. 183, pp. 925-939, 2018. https://doi.org/10.1016/j.jclepro.2018.02.224.

[24] D. Tang, M. Dai, M. A. Salido, and A. Giret, "Energy-efficient dynamic scheduling for a flexible flow shop using an improved particle swarm optimization," Computers in Industry, vol. 81, pp. 82-95, 2016. https://doi.org/10.1016/j.compind.2015.10.001.

[25] H. Piroozfard, K. Y. Wong, and W. P. Wong, "Minimizing total carbon footprint and total late work criterion in flexible job shop scheduling by using an improved multi-objective genetic algorithm," Resources, Conservation and Recycling, vol. 128, pp. 267-283, 2018. https://doi.org/10.1016/j.resconrec.2016.12.001.

[26] X. Li, W. Li, X. Cai, and F. He, "A hybrid optimization approach for sustainable process planning and scheduling," Integrated Computer-Aided Engineering, vol. 22, pp. 311-326, 2015. https://doi.org/10.3233/ICA-150492

[27] X. Wu and A. Che, "A memetic differential evolution algorithm for energy-efficient parallel machine scheduling," Omega, vol. 82, pp. 155-165, 2019. https://doi.org/10.1016/j.omega.2018.01.001.

[28] J. Batista Abikarram, K. McConky, and R. Proano, "Energy cost minimization for unrelated parallel machine scheduling under real time and demand charge pricing," Journal of Cleaner Production, vol. 208, pp. 232-242, 2019. https://doi.org/10.1016/j.jclepro.2018.10.048.

[29] M. Tan, Y. Chen, Y.-x. Su, S.-h. Li, and H. Li, "Integrated optimization model for industrial self-generation and load scheduling with tradable carbon emission permits," Journal of Cleaner Production, vol. 210, pp. 1289-1300, 2019. https://doi.org/10.1016/j.jclepro.2018.11.005.

[30] S. Mirjalili, "SCA: A Sine Cosine Algorithm for solving optimization problems," Knowledge-Based Systems, vol. 96, pp. 120-133, 2016. https://doi.org/10.1016/j.knosys.2015.12.022.

[31] G. I. Galinato and J. K. Yoder, "An integrated tax-subsidy policy for carbon emission reduction," Resource and Energy Economics, vol. 32, pp. 310-326, 2010. https://doi.org/10.1016/j.reseneeco.2009.10.001.

[32] Y. B. Park, C. D. Pegden, and E. E. Enscore, "A survey and evaluation of static flowshop scheduling heuristics," International Journal of Production Research, vol. 22, pp. 127-141, 1984. https://doi.org/10.1080/00207548408942436.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Dana Marsetiya Utama

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.